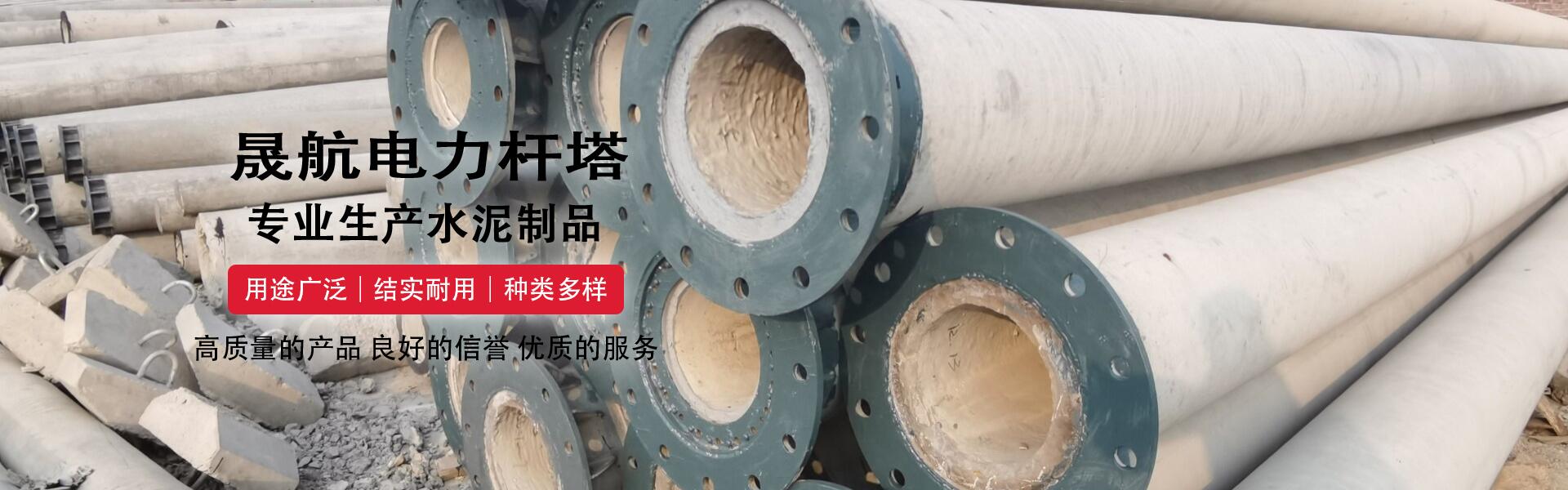

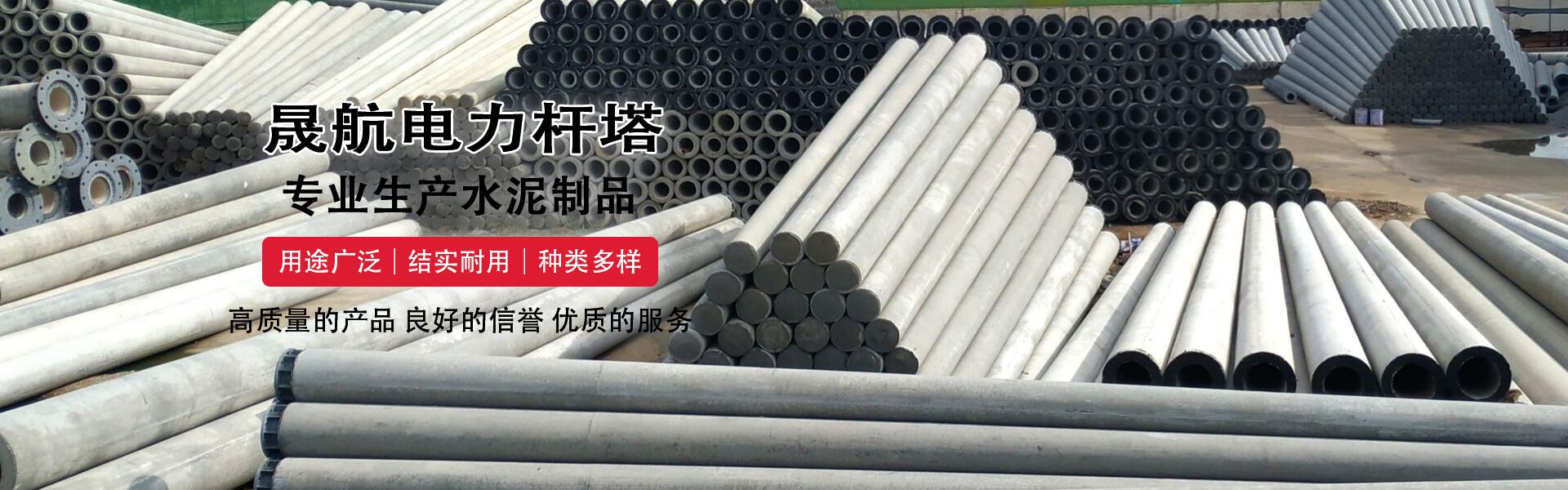

电线杆制作工艺

Manufacturing Technology of Wire Pole

水泥电线杆分为预应力和非预应力电线杆两种。

Cement poles are divided into two types: pre-stressed and non-pre-stressed.

工艺流程:

Technological process:

◆ 钢筋加工和钢筋笼制作:钢筋冷拔,切断,弯曲和绑扎

Reinforcement processing and cage making: cold drawing, cutting, bending and binding of reinforcing bars

◆混凝土配料、搅拌系统:混凝土配料与搅拌

Concrete proportioning and mixing system: concrete proportioning and mixing

◆ 电线杆成型:离心发成型圆形电杆(需要离心机、模具和布料机等设备),或震动成型其它类型电杆(需要布料机、震动台、模具等设备)

_Wire pole shaping: centrifugal shaping round pole (need centrifuge, die

and distributor equipment), or shaking shaping other types of pole

(need distributor, shaking table, mould and other equipment)

◆ 蒸汽养护:新成型电杆带摸静停一段时间,进入蒸汽养护室,养护几小时

Steam Maintenance: The new type of pole belt stops quietly for a period

of time, enters the steam maintenance room, and maintains for several

hours.

◆ 脱模和养护:电杆带模出养护室,脱模,清模,脱模的电杆继续保湿或泡水养护一段时间

Demoulding and maintenance: pole with mould out of maintenance room,

demoulding, demoulding, demoulding pole continue to moisturize or soak

in water for a period of time.

模具的投资较大,生产效率决定于模具周转率。

Mold investment is large, and production efficiency depends on the turnover rate of the mould.

生产水泥电线杆是在一定转速(产生足够的离心力,使水泥料形成中间空的电线杆)的钢模中用蒸汽养护而成。钢模是两个半模合成的,以便加料与取出成品。因此在成形之前需要对电线杆钢筋骨架(钢筋笼)的制作与符合比例要求的水泥料浆(水泥+石子+砂+水)的混合搅拌,因此其生产制作原理是简单的,但需要一定的吊运设备、场地及一定的机械设备。

The production of cement wire rod is cured by steam in a steel mould at a

certain speed (producing enough centrifugal force to form hollow wire

rod of cement material). Steel moulds are made of two half moulds for

feeding and removing finished products. Therefore, before forming, it is

necessary to mix the production of wire rod reinforced cage with cement

slurry (cement + stone + sand + water) which meets the proportionality

requirements. Therefore, the production principle is simple, but it

needs certain lifting equipment, site and certain mechanical equipment.