水泥电杆到处可见,而且也知道它是中空的,但是就是没有想过它是如何生产出来的,下面就是水泥电线杆的生产过程。

Cement poles can be seen everywhere, and we know that they are hollow,

but I have never thought about how they are produced. Here is the

production process of cement poles.

很多人都对电线杆生产的过程没有见过,中间空心是如何做出来的呢,电线杆生产过程是很繁琐的。要细心、严谨。针对每一个环节都要严把质量关。生产车间的工人也是辛苦的。

Many people have never seen the process of pole production. How is the

hollow in the middle made? The production process of pole is very

complicated. Be careful and rigorous. We should strictly control the

quality of every link. The workers in the workshop are also

hard-working.

这是生产的原材料,中间的是钢丝,远处的是沙子和碎石。

This is the raw material for production. In the middle is steel wire, and in the distance is sand and gravel.

图片

picture

1、首先需要将钢丝盘直,屋子里面有一个盘条机,因为逆光没有拍到,它把一捆一捆的钢丝盘直。。

1. First of all, you need to make the steel wire straight. There is a

wire rod machine in the room. Because the backlight has not been

photographed, it makes a bundle of steel wire straight..

图片

picture

2、根据电杆的长度,将盘直的钢丝截成需要的长度,钢丝是要做成水泥电线杆的配筋(相当于纬线)。

2. According to the length of the pole, the coiled steel wire is cut

into the required length. The steel wire is to be made into the

reinforcement (equivalent to weft) of the cement pole.

图片

picture

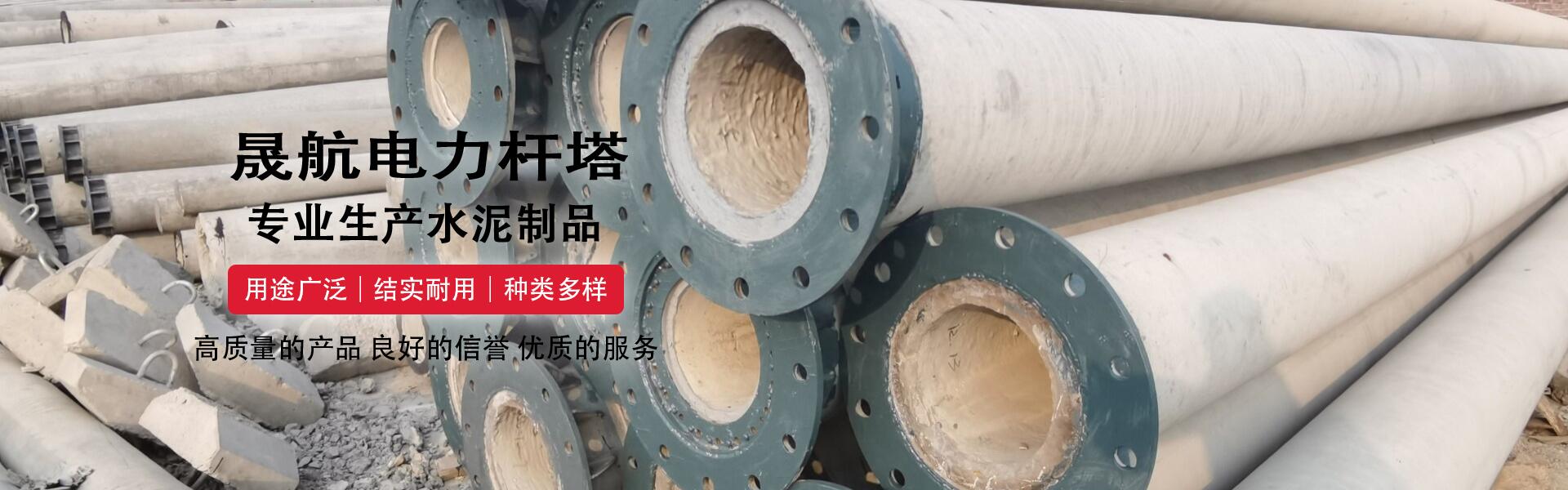

3、这就是水泥电杆的模具,两半的。

3. This is the mold of the cement pole, two halves.

图片

picture

4、把盘直的钢丝每根电杆至少8根筋,我们公司为了稳固都要求是12根筋(这可是多了不止一根筋,)。同时用细钢丝盘成罗圈的纬线,环泥杆 保定古筝 塑料增韧剂 拱形护坡模具 保定空调维修 托辊生产线绕着作为纬线的钢丝,结合的地方用铁丝绑牢,这样在模具中就有了水泥电杆的龙骨。然后用一定比例的水泥浇灌满。

4. Each pole should have at least 8 steel bars. Our company requires 12

steel bars for stability. At the same time, we use thin steel wire to

form a circle of weft wire, which is surrounded by the steel wire as the

weft line, and bind the joint place with iron wire, so that there is

the keel of cement pole in the mold. Then fill it with a certain

proportion of cement.